Autoclave Design of Different Materials for a High-temperature and High-pressure Environment

Published on: August 20, 2024 Topics: Mineral Processing and Mining, PYROFLEX®During the past three decades, pressure oxidation (POX) autoclaves have become the preferred method for extracting metals such as gold, copper, nickel and zinc. Compared to traditional smelting, POX offers higher yields, lower energy consumption and better environmental protection. POX autoclaves operate under corrosive conditions, often using sulfuric acid in the process fluid or slurry. The operating temperature and pressure vary depending on the ores and the metals being leached. For example, a typical gold POX application operates at temperatures between 190 to 230° C and pressures from 2.1 to 3.6 MPa.

Brick lining System of a POX autoclave

A typical POX autoclave is constructed from carbon steel pressure vessels lined with a brick lining system comprising acid-resistant membranes, refractory bricks, mortar and auxiliaries. This composite lining system is meticulously designed to handle the autoclave’s harsh operating conditions.

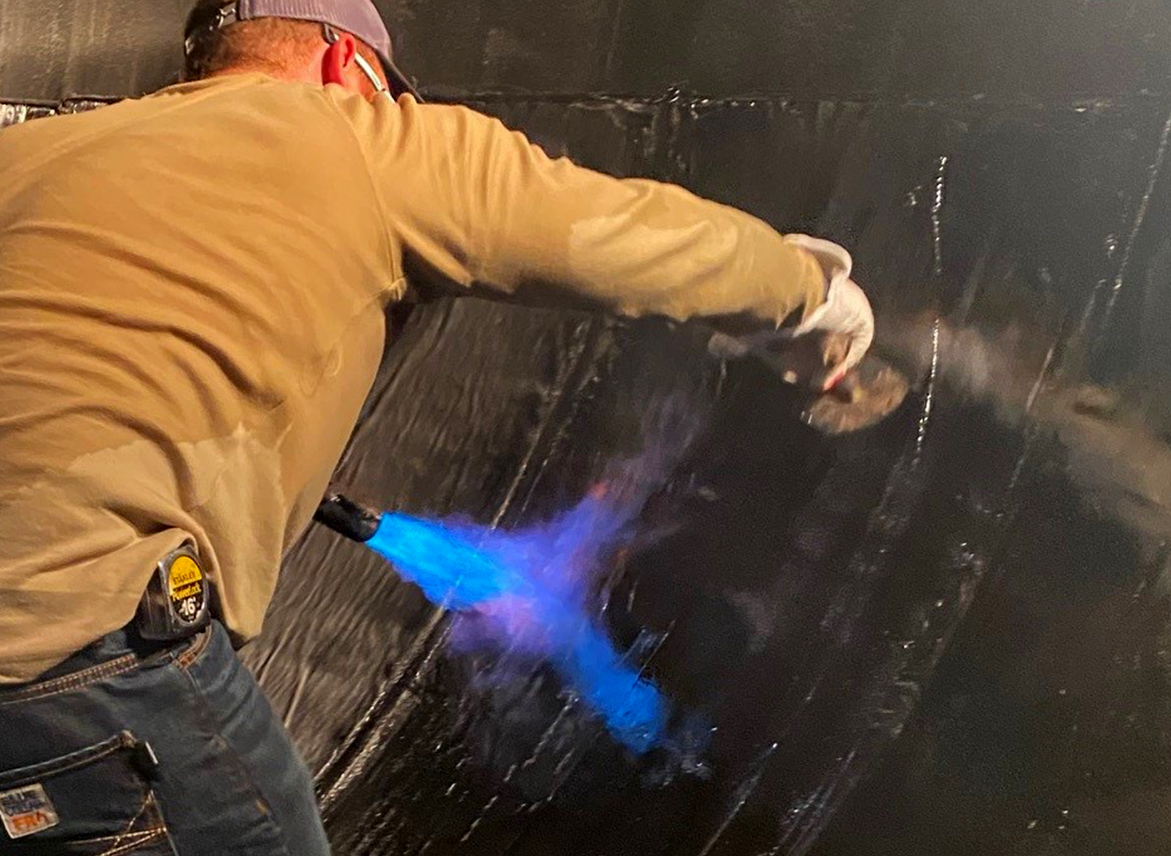

Autoclave membrane linings

The polymer membrane serves as the final barrier, preventing acidic slurry from attacking the carbon steel vessel. A good membrane must be impermeable to chemicals, adhere well to the steel, and handle thermal stresses. Due to their different thermal expansion coefficients, the differential expansion between the steel and ceramic brick should also be accommodated. Additionally, the membrane must adapt to the brick’s moisture expansion over time, ensuring structural integrity and preventing premature failure.

Knight Material Technologies product focus:

-

PYROFLEX® Acid-Resistant Membranes – a flexible, non-porous, uniformly thick sheet membrane used as an impervious barrier between acid-resistant brick and corrosion-prone steel.

Autoclave refractory brick

The refractory ceramic brick acts as the first line of defense against acid and erosion from the process slurry. It also serves as a thermal barrier, protecting the membrane and allowing the system to operate at high temperatures. Typically, two to three courses of 76 mm thick bricks are used, falling under the Type II category as defined by ASTM C-279. These bricks are formulated to minimize moisture expansion, which could otherwise cause stress and cracking over time.

Knight Material Technologies product focus:

-

DURO® Acid Brick – maintains corrosion resistance in high-temperature environments and conforms to ASTM 279 specifications.

Mortars for autoclave hydrometallurgy

Bricks are keyed into the round steel vessels with minimal mortar, typically around 5 mm thick, to ease installation and provide additional membrane protection. The mortar used must possess strong mechanical and bonding strength, able to withstand acid corrosion and slurry erosion at high temperatures. Regular inspections during maintenance shutdowns are crucial, with necessary mortar repairs or brick replacements to ensure long-term durability.

Knight Material Technologies product focus:

-

ACIDSILTM SR MORTAR – A halogen-free silicate-type mortar made with selective size-graded silica fillers. The ACIDSIL SR MORTAR liquid binder is a two-component silicate solution designed for both reduced set time and excellent resistance to steam.

-

GLYSIL 90TM MORTAR – A litharge-glycerol mortar designed for use in sulfuric acid/oxidizing environments. The GLYSIL 90TM MORTAR is effective at temperatures exceeding the limits of most organic mortars.

-

ACIDSILTM Z MORTAR – A halogen-free silicate-type mortar made with selective size-graded silica and zircon fillers. The liquid binder is a potassium silicate designed for high loading and good workability. In steam impingement environments, ACIDSILTM Z mortar holds up better than typical silicate mortars. With limited chemical expansion, this mortar was specifically developed to withstand corrosive and abrasive acid slurry.

Autoclave compartment walls and baffles

In horizontal autoclaves, compartment walls divide the vessel into sections, decreasing the wall height from the first to the last compartment. Initially constructed from acid-resistant brick and mortar, these walls now commonly use titanium alloy due to its superior tensile strength and acid resistance. Custom-designed using Finite Element Analysis (FEA), titanium compartment walls can withstand the agitation load and slurry mass, offering enhanced durability.

Similarly, anti-swirl baffles are now made from titanium and mounted with legs embedded under face course bricks. This construction ensures stability and effectiveness in guiding the slurry flow within the autoclave.

Nozzle lining

Nozzle linings are critical components of the acid-resistant brick lining system, subjected to higher thermal and mechanical stress. A typical nozzle liner design involves multiple materials, including titanium inserts, acid-resistant mortar, custom PTFE tiles, refractory tiles and Alloy 625 cladding. Each material’s properties, such as density, thermal expansion coefficient, modulus of elasticity, Poisson’s ratio, and thermal conductivity, are carefully considered to ensure the lining’s structural integrity and reliability.

Typical material properties

| Property | Titanium Alloy | Mortar/Grout | PTFE Tile | Brick | Alloy 625 Clad |

|---|---|---|---|---|---|

| Density (kg/m3) | 4,491 | 2,178 | 2,166 | 2,275 | 8,400 |

| Thermal Expansion Coefficient (/°C) | 9.18×10–6 | 1.00×10–5 | 1.51×10–4 | 5.40×10–6 | 1.30×10–5 |

| Modulus of Elasticity (MPa) | 1.00×105 | 3.10×104 | 68.90 | 4.80×104 | 2.00×105 |

| Poisson’s Ratio | 0.37 | 0.17 | 0.36 | 0.20 | 0.29 |

| Thermal Conductivity (W/m-K) | 16 | 1.3 | 0.3 | 1.3 | 11 |

Constructing POX autoclaves with dissimilar materials such as ceramics, metals, and polymers requires meticulous design and coordination. Each material’s unique properties must be considered to ensure the autoclave’s reliability and long-term operation. Regular maintenance and inspections are essential to address any wear and tear, ensuring the autoclave continues to function efficiently under harsh conditions.

Get the full white paper, Autoclave Lining Construction with Dissimilar Materials, for more information.