This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Knight Materials

| % VOID SPACE | SURFACE AREA | PACKING DENSITY | CRUSH STRENGTH | |

|---|---|---|---|---|

| FLEXERAMIC® Structured Packing TYPE 48 | 79% |

63 ft2/ft3 208 m2/m3 |

30 lbs/ft³ 478 kg/m³ |

67 psi 4.7 kg/cm² |

| FLEXERAMIC® Structured Packing TYPE 88 | 85% |

38 ft2/ft3 125 m2/m3 |

20 lbs/ft³ 318 kg/m³ |

30 psi 2 kg/cm² |

Mass Transfer of Sulfuric Acid

| (Imperial) | ||||

|---|---|---|---|---|

| Packing | 3” FLEXISADDLES® | FLEXERAMIC® Structured Packing 88 | FLEXERAMIC® Structured Packing 88 | FLEXERAMIC® Structured Packing 88 |

| Diameter | 21'0" | 21'0" | 21'0" | 18'3" |

| Packed Height | 10' | 10' | 10' | 10' |

| Gas Flow (lb/hour) | 500,000 | 500,000 | 650,000 | 500,000 |

| Acid Rate (gpm) | 4,700 | 4,700 | 6,100 | 4,700 |

| Pressure Drop ("w.c.) | 6 | 2 | 4 | 4 |

| % Flood at Bottom (Max.) | 80% | 63% | 80% | 80% |

| Acid Production (STPD as 100% H2SO4) | 870 | 870 | 1130 | 870 |

| Power Consumption (kW) | 130 | 50 | 105 | 80 |

| (Metric) | ||||

|---|---|---|---|---|

| Packing | 3” FLEXISADDLES® | FLEXERAMIC® Structured Packing 88 | FLEXERAMIC® Structured Packing 88 | FLEXERAMIC® Structured Packing 88 |

| Diameter (m) | 6.4 | 6.4 | 6.4 | 5.6 |

| Packed Height (m) | 3 | 3 | 3 | 3 |

| Gas Flow (kg/hour) | 230,000 | 230,000 | 300,000 | 230,000 |

| Acid Rate (m3/hour) | 1,100 | 1,100 | 1,400 | 1,100 |

| Pressure Drop (mm w.c.) | 150 | 60 | 100 | 100 |

| % Flood at Bottom (Max.) | 80% | 63% | 80% | 80% |

| Acid Production (STPD as 100% H2SO4) | 800 | 800 | 1040 | 800 |

| Power Consumption (kW) | 130 | 50 | 105 | 80 |

Structured Packing

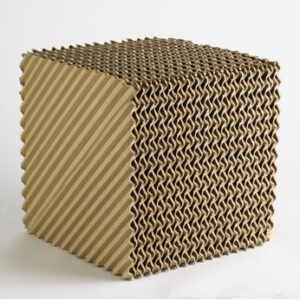

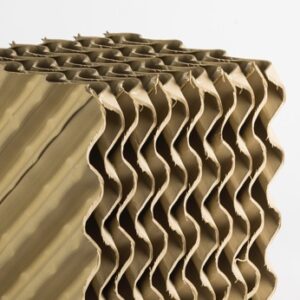

FLEXERAMIC® Ceramic Structured Packing

Our geometrically arranged corrugated sheets provide greater resistance to fouling than random packing, while our design provides high capacity, higher efficiency and lower pressure drop than any random packing and most trays that are available today.

Revamp existing packed or tray columns with structured packing from Knight Material Technologies offers an economical alternative to other media. FLEXERAMIC® structured packing affords plant operators increased separation efficiency and operation capacity, lower pressure drop and often significantly lower energy costs for distillation or absorption operations.

Competitive Advantages

- Made in America

- FLEXERAMIC® structured packing can process 30% more gas flow than ceramic saddles (random packing)

- 30% more gas flow results in 30% more acid production

- 50% lower pressure drop as compared to ceramic saddles (random packing) with the same gas flow

- Benefit is 50% energy savings

Capabilities

- Proper mixing throughout the entire chamber

- Reduced channeling of liquid and vapor, providing more effective contact of acid and gas

- Vertically oriented ceramic corrugated sheets reduce resistance to fluid flow

- Hundreds of installations; >100 in sulfuric acid alone

- Excellent resistance to fouling

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.