Posts about:

Linings

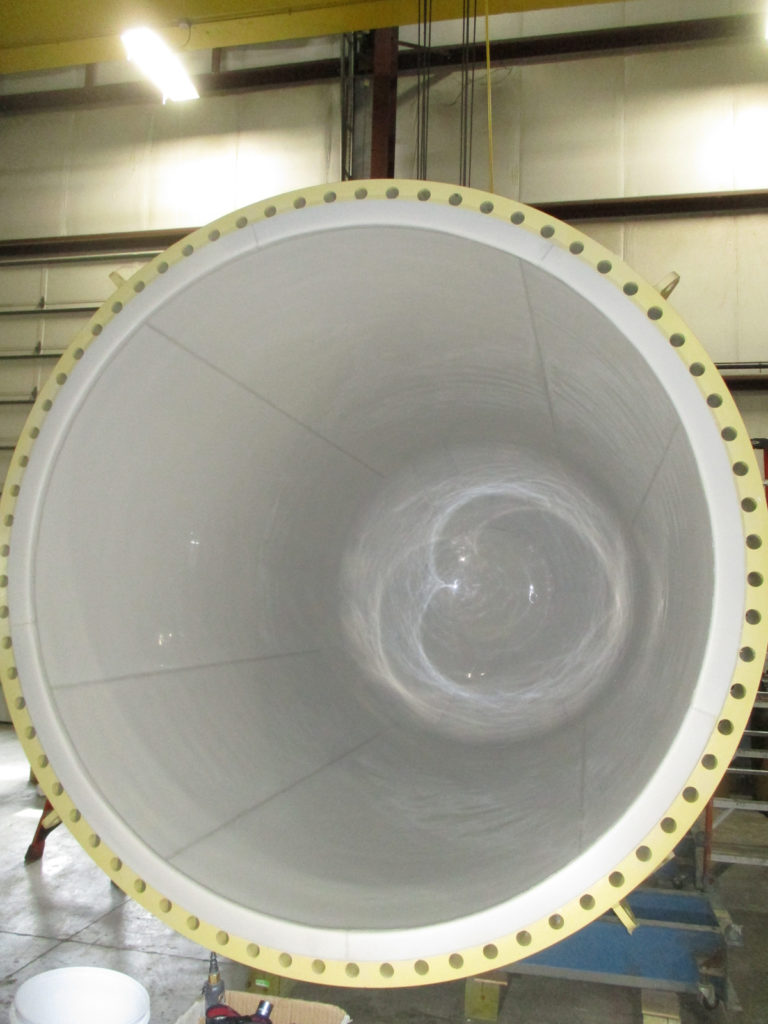

For Containers Containing Highly Corrosive Chemicals Or Protecting High-purity Liquids, The Lining Of Choice Is Often High-performance Fluoropolymers. Over Time, The Demanding Conditions And Harsh Chemicals These Tanks Encounter Can Compromise Lining Integrity, Requiring Professional Assessment And Maintenance. Electro Chemical Engineering And Manufacturing Co. Provides ISO Certified Inspection And Relining Services To Help Companies Pass Inspection And Get ISO Tanks Back On The Road Quickly.

Read BlogDiscover Key Differences Between PTFE And PFA Linings And How Each Protects Against Corrosion, Chemical Attack, And Process Failures In Harsh Environments.

Read BlogDiscover The Critical Differences Between Fluoropolymer Linings And Fluoropolymer Coatings. Learn How Each System Protects Equipment In Harsh Chemical Environments And Ensures Longevity

Read BlogIn A Recent Move Designed To Strengthen Its Core Competencies, Knight Acquired Electro Chemical Engineering And Manufacturing Co. (ECM) In Emmaus, PA. Electro Chemical Also Operates A Division In Vancouver, British Columbia, Called Superior Dual Laminate Products (SDL). This Merger Gives Customers Unparalleled Access To The Broadest Available Range Of Products And Services In The Corrosion Protection Industry.

Read BlogFluoropolymer Linings Are A Proven Cost-effective Solution In Many Corrosive Environments. Properly Selected, They Are Less Prone To Chemical Attack And Less Fragile Than Other Lining Options. Fluoropolymer Linings Can Also Be Repaired And Replaced To Extend The Life Span Of The Equipment They Are Protecting.

Read BlogAlthough Dual Laminates Have Been Around Since The 1960s, Finding A Universally Agreed Upon Set Of Best Practices For Incorporating These Fiber Reinforced Plastic (FRP) Thermoplastic-lined Products Into Your Tanks And Piping Systems Is Nearly Impossible. In Fact, The First Standards For Welding Of Plastics, Including Liners, Were Not Even Introduced Until 2015.

Read BlogWhen You Talk About Fluoropolymer Lining Protection Against Chemical Corrosion And Permeation, PFA (perfluoroalkoxy) Delivers The Highest Level Of Resistance. We Can Thank The Strength Of The Fluorine-Carbon Bond Within The PFA Polymer Chain For Its Incredible Inertness. These Bonds Are So Tight And Enduring That They Simply Do Not Allow Other Atoms Or Molecules To Separate Them. This Makes PFA The Strongest Of The Fluoropolymers For Preventing Chemical Corrosion, Permeation, And Reaction.

Read Blog