The Power of Collaboration: Corrosion Resistance Times Three

Published on: February 21, 2024 Topics: Chemical Processing, LiningsCustomers Can Now Realize Synergistic Benefits for Industrial Applications

Corrosion and rust can begin subtly and insidiously, presenting themselves as well-known, recurring challenges. Industrial applications within chemical processing often rely on highly corrosive chemicals such as sulfuric acid for various purposes. Companies require specialized expertise to design and fabricate systems and containment structures that protect capital equipment and other assets while safeguarding workers and the environment.

A corrosion-resistant system helps companies extend the service life of towers and structures while adhering to required regulatory standards for emissions of volatile organic compounds (VOCs) generated during operations. Many companies have found a solution to these challenges by working with Knight Material Technologies in Canton, Ohio.

In a recent move designed to strengthen its core competencies, Knight acquired Electro Chemical Engineering and Manufacturing Co. (ECM) in Emmaus, PA. Electro Chemical also operates a division in Vancouver, British Columbia, called Superior Dual Laminate Products (SDL). This merger gives customers unparalleled access to the broadest available range of products and services in the corrosion protection industry.

The KMT headquarters are in Canton, Ohio.

The KMT headquarters are in Canton, Ohio.

Three-in-one: The combined corrosion resistance expertise of KMT, ECM and SDL

Knight is a well-established industry leader for corrosion-resistant materials and installations, with a history of serving its customers since 1910. Knight has built a stellar reputation for designing, installing, servicing and manufacturing custom acid-resistant linings targeting highly corrosive processes for companies in more than 40 countries.

Electro Chemical has been a leader in high-performance fluoropolymer-lined vessels and corrosion protection systems for close to 75 years, following its inception in 1949. The company’s corrosion-resistant lining and coating systems have been integral in safeguarding pressure vessels, tanks, distribution equipment and internal components across various industries. With a strong focus on innovation and technology, ECM has consistently delivered reliable and durable solutions while offering cost advantages to its customers.

ECM excels at ultra-high purity lined vessels

ECM excels at ultra-high purity lined vessels

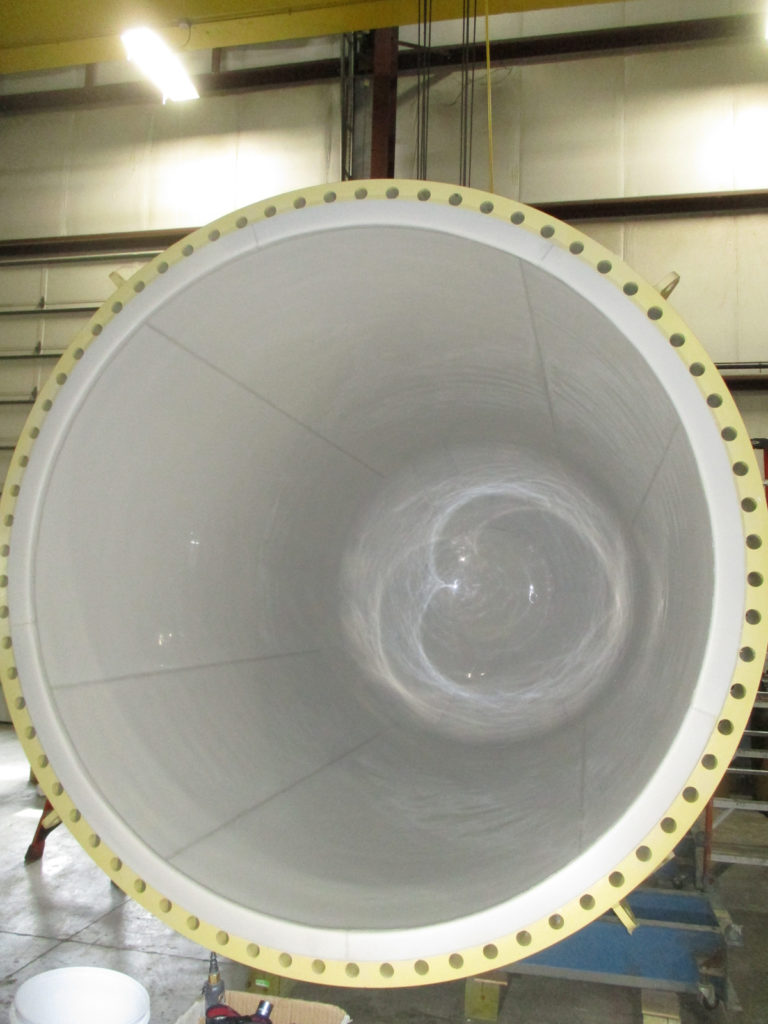

Superior Dual Laminate Products, a subsidiary of Electro Chemical, specializes in high-quality fiber-reinforced plastic (FRP) dual laminate equipment, including piping, headers, tanks and specialty items. Industries dealing with highly corrosive substances, such as the chlor alkali sector, favor SDL’s FRP corrosion-resistant solutions as lightweight yet durable and cost-effective options for the aggressive chemicals used during production.

The combined, collaborative efforts from these three previously separate firms help supply industry-leading linings, coatings and systems solutions for some of the most demanding applications within manufacturing and industry.

This integration offers customers seeking corrosion-resistant solutions a comprehensive suite of innovative materials and services. The offerings span a product range that includes:

- acid-resistant linings

- structured and random packing materials

- liquid distributors

- fluoropolymer lining and coating systems

- dual laminate components and more

The three companies’ various locations offer customers an expanded geographic reach for service teams of trained technicians, which can serve customers’ diverse and dispersed needs north and south of the US-Canadian border.

The benefits of this collaboration became particularly evident when examining a recent project completed for a defense contractor in Oregon, which needed assistance with its sulfuric acid absorption tower.

Sulfuric Acid plants are exposed to highly corrosive chemicals

Sulfuric Acid plants are exposed to highly corrosive chemicals

Defense contractor benefits from corrosion resistance collaborative expertise

This defense contractor was affected by the scarcity of skilled labor and the availability of people with the necessary expertise to diagnose the needs of its sulfuric acid processing tower’s internal components quickly, efficiently, and accurately. Navigating this trained labor shortage was just one barrier. The company also wanted to complete the inspection and any repairs or replacements within the confines of its annual scheduled shutdown of just one month’s time. And the company needed its system to adhere to increasingly stringent air quality requirements—an environmental protection trend spreading across the United States.

The presence and availability of trained service technicians from SDL, located close to the plant on the US West Coast, helped achieve the company’s objectives for the tower inspection. In addition, it freed up internal resources for other areas of the operation that also required inspection and repairs during the shutdown period.

Parts availability proved to be a huge asset supplied by SDL as well. While other suppliers quoted timelines of up to six weeks for simple parts such as clamps and fittings, SDL supplied them within six days. This allowed the project to stay on track to meet the contractor’s time limit.

In the end, this sulfuric acid absorption tower build was a complex project, with the combined expertise of Knight, ECM and SDL able to provide the total corrosion-protection product and service package from one company, with just the right balance between performance and cost-effectiveness. The tower internals represent the latest advancements for the design and fabrication of the liquid distributor and structured packing blocks, among other components.

Read more of the details in our full case study about this project here.

The collaborative expertise of Knight Material Technologies, Electro Chemical Engineering and Manufacturing Co. and Superior Dual Laminate Products can offer customers across North America a comprehensive suite of innovative materials and services to tackle corrosion resistance for demanding industrial applications. The depth of industry knowledge and expertise, the level of customer service and breadth of the product line offered through this new alliance can deliver rapid, efficient and cost-effective solutions. Come to us with your processing objectives or emissions concerns. Our expert teams can help find solutions tailored to your corrosion protection challenges.