Knight Materials

Specialty Random Packing

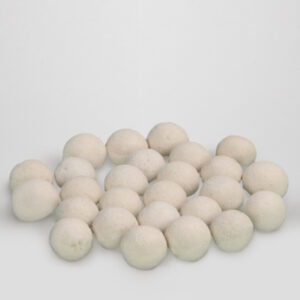

KRYPTOKNIGHTTM Inert Ceramic Balls

A very versatile alumina ceramic support media used for multiple applications, including reformers, converters, crackers, refinery and dryers.

KRYPTOKNIGHTTM M Inert Ceramic Ball – 20% Al2O3 aluminosilicate ceramic support media with all the properties necessary for excellent performance as the support media in molecular sieve desiccant dryer applications, as well as in many refinery applications. Whether drying a vapor or a liquid, at high temperature or low temperature, KRYPTOKNIGHTTM M Inert Ceramic Balls have the chemical stability (inertness), mechanical strength, roundness, and low porosity required to provide excellent service at an outstanding price.

KRYPTOKNIGHTTM H Inert Ceramic Ball – 30% Al2O3 aluminosilicate ceramic support media made from a formula with over 23% alumina content, designed for the tough service conditions in many applications in petroleum refining and chemical manufacturing. Hydrotreating, isomerization, catalytic reforming and hydrocracking are some of the many fixed-bed catalytic processes for which KRYPTOKNIGHTTM H inert ceramic balls may be used.

KRYPTOKNIGHTTM T Inert Ceramic Balls – 94% Al2O3 aluminosilicate ceramic support media made from a formula with over 94% alumina content, designed for the tough service conditions in many applications in petroleum refining and chemical manufacturing. Hydrotreating, isomerization, catalytic reforming and hydrocracking are some of the many fixed-bed catalytic processes for which KRYPTOKNIGHTTM T inert ceramic balls may be used.

KRYPTOKNIGHTTM A Inert Ceramic Ball – Greater than 99% Al2O3 alumina support media, an excellent choice for processes where steam is present and may cause leaching of silica from a typical aluminosilicate media. A high-alumina media also produces good results when polymerization is a problem in the process. Typical applications include steam methane reformers, ammonia plant shift converters, C4 crackers, methanol production, and hydrogen plants, KRYPTOKNIGHT A is very low in silica content and resists the leaching which may poison catalyst or even damage downstream equipment. It is a fully fired ceramic with low dusting potential and high spalling resistance.

RASCHIG RINGS

Designed for high structural strength with no soluble bond, low coefficient of thermal expansion, high temperature capabilities, excellent corrosion resistance to acidic and caustic environments, light weight and fully carbonized to eliminate extractable impurities.

½”

¾”

1”

1½”

2”

3”

Ceramic

Carbon

Graphite