Knight Materials

History Timeline

A New Day for Knight – Knight Changes Ownership

Additionally, Knight demonstrates ongoing excellence by continuing to renew their ISO 9001 certification to offer the best in products for their customers.

Additionally, Knight demonstrates ongoing excellence by continuing to renew their ISO 9001 certification to offer the best in products for their customers.

The Era for Preparing for Growth – Strengthening Products and Services Lines

Knight Increases Product Offering Preparing for New Growth

Now in the 2000s, Knight was preparing themselves for the growth they saw ahead. First, the plant went through earning ISO 9001 certification, enhancing the company’s reputation for innovation and standards. Also during this time, Knight acquired DURO® Acid Brick, adding to the line of acid-resistant construction materials with excellent corrosion resistance in high-temperature environments. Knight also introduced the Epoxigard HC Injection to repair damage in sulfuric towers caused by acid leaks.

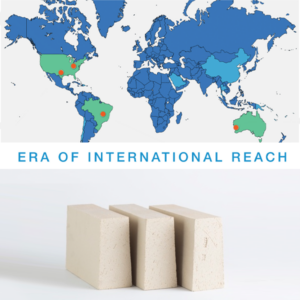

The Era of International Reach – Rapid Global Expansion

Knight Expands into New Markets and Adds New International Offices

During the 00s, Knight has projects worldwide, including Brazil, China, Australia, Saudi Arabia, and more. This leads to new additional Knight offices in Australia to service the Pac-Asian Market and a joint venture in Brazil for the growing chemical processing and sulfuric acid-producing markets. In addition, new random packing shapes and formulas are created to meet increased international demand and production capabilities for FLEXERAMIC® Structured Packing increase. The PV33P brick was developed during this time and quickly became the industry standard in the Hydrometallurgical industry.

The Relocation Era – Increasing Manufacturing Capabilities

Koch Knight Moves to New Location Offering Expanded Capacity

Knight moves to an existing ceramics plant in East Canton, Ohio during the 90s. The larger facility offers additional capacity, including a new line of random packing, Knight’s LPD® Random Packing. The unique design of the random packing saddle becomes the most widely used random heat transfer on the market. Other innovations during this period include FLEXISADDLE® HPC packing, KNIGHT-WARE® AP 302 Brick and two new mortars for the hydro-metallurgical autoclaves, Glysil 90 and ACIDSIL.

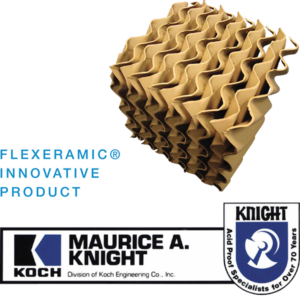

The Era of Change – Bringing a Knight to Koch Engineering

Knight Becomes a Division of Koch Engineering Co, Inc After Purchase from Koch Engineering Company, Inc.

In 1981, Koch Engineering Company, Inc., of Wichita, Kansas, bought Knight, which then became Koch Engineering Knight Division. Knight’s expertise was a welcome addition to the Koch family of companies working in the refining, chemical and petrochemical industries. Also, during the 80s, the innovative FLEXERAMIC® Ceramic Structured Tower Packing was developed. FLEXERAMIC® Structured Packing had several solutions to problems including mass transfer, lower pressure drop and lower energy costs of operation. As a result, the unique geometric design has become the industry leader in structured media.

The Rebuilding and Recovery Era – Recovery from Challenge

The Knight Company Loses Plant and Devastating Offices in Fire

A lightning strike razed almost all the plant in July 1976. A few outbuildings and inventory were spared, including the KNIGHT-WARE® products and PERMANITE® structured products, which could continue fabrication. The first building to be rebuilt was the office so the company could communicate with customers, and a shipping department to continue shipping what was available. Although reconstruction took nearly 3 years, the new manufacturing plant was better than ever, housing the latest technology.

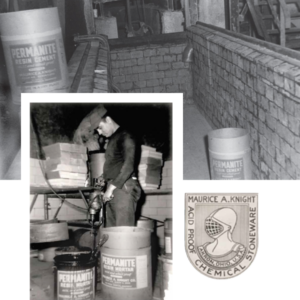

The Mortar Era – More Innovations for Installations

New Mortars to Respond to a Changing Market

The technology of the acid-proof brick manufacturing and installation market was changing, and the Knight company responded by developing new mortars. PERMANITE® is a furan resin-based mortar for floors or linings of chemical processing equipment with a quick setup and a dense, non-porous joint. ACIDSIL® is a quick-setting, acid-proof, silicate-based product resistant to all acids except hydrofluoric. The final new mortar, KABO Mortar, is a phenolic resin for brick linings in pickling tanks, absorption towers, processing vessels, storage tanks and acid-proof brick floors.

The Acid Proof Construction Era

A New Company is Formed to Guarantee By-the-book Installation of Knight Products

Maurice Knight develops the Acid Proof Construction (APC) Company to ensure the proper installation of Knight products. Field offices are established in Akron, Ohio and Houston, Texas. Led by experts, the APC Company quickly grew and solidified new installation techniques. Newly acquired equipment from Europe led to the development of a new product line to handle the disposal of acids and corrosive liquid waste. The new equipment neutralized the acid waste so it could be safely discharged into regular sanitary sewer systems.

The War Era – Innovations Continued Amid War Supplying

Even While Supplying War Efforts and Losing Employees to Armed Services, Innovations Continued

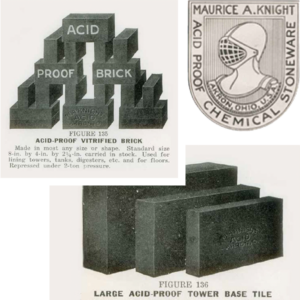

Although circulated, the rumors of covert operations were never confirmed as employees wouldn’t talk about any government operations that might have occurred before or after the war. The company went through many employee changes as workmen volunteered or answered the draft for the armed services. Many who could continue working at the plant had been there since the beginning, even bringing their sons to learn the ceramics trade. Innovations during this time include Acid Proof brick and tile.

The Era of Innovations – New Innovations to the Industry

Affected by the Great Depressions, Maurice Knight Soldiers on with New Innovations

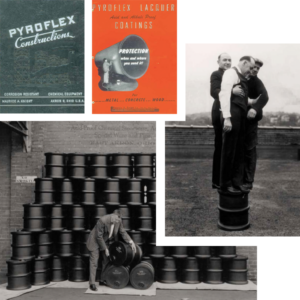

Four inventions change the company and the industry. 1 – The Berl Saddle invented by Dr. Ernst becomes the industry staple for scrubbing reaction, fractionating and drying towers. 2 – Pyroflex® Membrane. A flexible, non-aging asphaltic/rubber that becomes a cornerstone of Knight Acid Proof Construction. 3 – Deairating Machine. A major technological advance in clay processing, it prepares clays and extrudes shapes for chemical stoneware. 4 – General All -Rubber Drums. Lightweight and acid-resisting, these drums were practically indestructible shipping containers.

The Era of Expansion – New Innovations and Services

The Maurice Knight Company Quadruples in Size

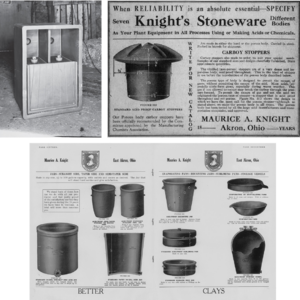

During the 1920s, chemical stoneware became required in laboratories, and Knight jumped at the opportunity. Soon KNIGHT-WARE® Ceramic is the standard equipment in the largest hospitals and laboratories throughout the country. Innovation continues with the invention of the Porous Carboy Stopper which keeps acid from escaping but allows gases to vent. This ends the risk of exploding carboys and soon becomes mandatory equipment for the industry.

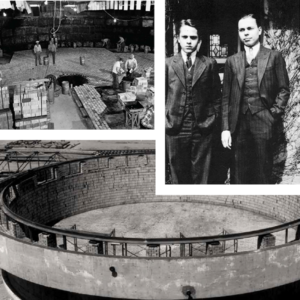

The Beginning – Maurice A. Knight Buys Pottery Plant

First Ceramic in USA Tough Enough to be Formed into Large Pieces

Maurice A. Knight buys the F.H. Weeks Pottery Plant on Kelly Avenue and creates a new type of stoneware vitrified all the way through. This new stoneware does not depend on glaze for acid resistance and is tough enough to be formed into large pieces. He creates the slogan “It is the Body Itself.” However, the plant’s entire output was turned over to the government at the onset of WW1.