Knight Materials

Media Overcomes Abrasive Dust Challenges in Fiberglass RTO

Situation: Fiberglass Manufacturer Resolves Frequent RTO Media Plugging

A major fiberglass manufacturer in the southeastern United States produces fiberglass insulation products sold in big box home improvement retail outlets, as well as commercial fiberglass products used by original equipment manufacturers (OEMs) in major appliances such as HVAC units and other consumer goods. The company operates two production lines to manufacture these diverse products, using high heat to melt raw sand to produce fiberglass material.

Solution

The plant engineering manager evaluated the RTO system and its performance, seeking a way to increase the lifespan of the ceramic media to decrease production downtime. He looked for alternative solutions to the traditional monolithic block media currently in use.

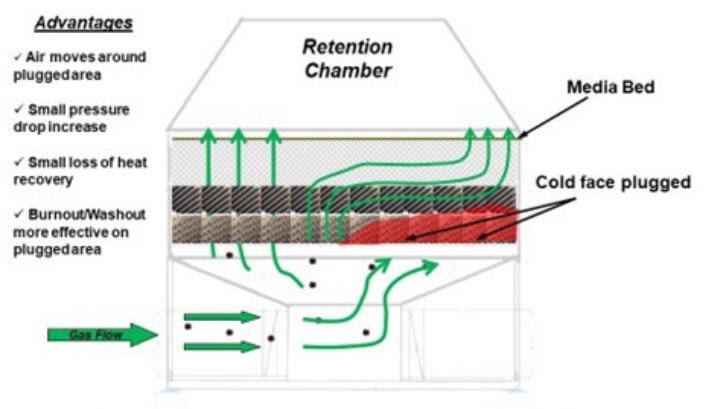

The company decided to switch to Knight Material Technologies’ FLEXERAMIC® structured packing media. This uniquely engineered corrugated media offered several key benefits due to its proprietary design, offering distinct advantages compared to other forms of media. Particularly when compared to traditional, straight-channel monolithic blocks, the FLEXERAMIC packing media directly addressed the company’s challenges:

-

Increased Media Lifespan

The FLEXERAMIC media has lasted 2-3 years between replacements, compared to the 3-6 months with the previous block media, and had a shorter downtime during switchouts. This dramatically reduced costly downtime from 4-5 days every 3-6 months to just 2-3 days every 2-3 years.

Fiberglass production is a commodity business, where even half a percent of lost production time can significantly impact profitability. Previous block media stole at least a week’s worth of production time for its replacement. This equals a two-percentage point loss in production time that the company regained by making the switch.

-

Improved Dust Handling

The corrugated design of the FLEXERAMIC media increases airflow and, therefore, is better able to handle the high levels of abrasive fiberglass dust without plugging as quickly. This allowed the RTO to operate more efficiently and maintain a lower pressure drop.

-

Enhanced Efficiency

The FLEXERAMIC media maintained higher thermal efficiency and lower pressure drop compared to the previous block media, reducing the burden on the RTO’s fans. This helped extend the lifespan of critical capital equipment. More significant was its ability to help the company remain in compliance with emissions standards.

In addition, the FLEXERAMIC solution was a direct swap-in replacement, allowing for a straightforward installation without major modifications to the existing RTO system.

It should be noted that the pressure drop is directly related to energy costs, and in most cases, the FLEXERAMIC media would provide significant energy savings to the manufacturer. Due to the fact that the melting process within fiberglass production draws 99% of the facility’s total energy expenditure, in this case, although energy was spared, it was not the main factor in the company’s decision to switch from monolithic blocks to FLEXERAMIC.