Knight Materials

EPOXIGARD™ HC Injection — Repairing Acid Damage in Process Towers

Discover how Knight Material Technologies’ EPOXIGARD™ HC Injection restores integrity to acid-damaged towers.

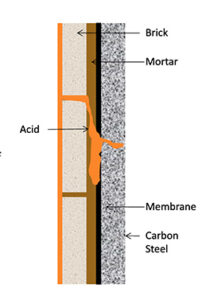

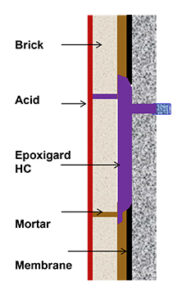

How it works

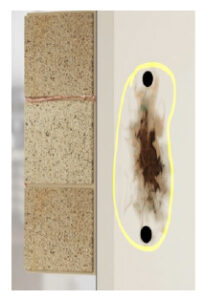

- Void location locations behind the shell are identified.

- Holes are drilled at a low point below the suspected void and a high point above it.

- Using low-pressure injection equipment, the low-viscosity EPOXIGARD HC fills the voids and any small cracks going from the injection port.

- The EPOXIGARD HC is a 100% solid material with no VOCs, so it will harden and cure into a membrane without creating new passes for the acid to reach the steel shell.

| 1.

|

2.

|

3.

|

Benefits of Using EPOXIGARD HC Injection

The turnkey proprietary formulation goes beyond previous repair methods and counters previous shortcomings to provide a solution that mitigates tower replacement or internal brick lining reconstruction. The benefits of EPOXIGARD include:

Why Other Methods Used in Sulfuric Acid Repairs Don’t Work

Over many years, various types of repair methods have been attempted to repair the leakages of sulfuric acid from damaged towers. Here are some of those methods and the reasons why they haven’t performed well:

- Steel Patch on the outside of the tower. There are a couple of reasons this won’t work. First, the steel plate welding heats the membrane, typically rubber or Pecora, that is not heat-resistant, thus further providing areas for corroding the protective layer/steel. This method also doesn’t do anything to stop the initial problem which is acid migration through the brick and mortar. The patch will fail in approximately one year or less between these two issues.

- Box on the outside filled with potassium silicate. Potassium silicate is chosen because it is the same composition as the mortar inside the tower. Boxes have even been made as large as two meters by three meters as a precaution. However, potassium silicate hardens immediately once in contact with the acid, which may come as a loss to the shell behind it. In addition, the mixture depends on gravity to flow to the desired location, so it will only flow into the corroded hole but will not reach voids behind the steel to infiltrate cracks.

- Asphaltic mixture. The asphaltic mixture – Pecora Mastic – seems like a good idea because it is similar to the membrane material used inside, if not the same. For injecting it into the appropriate areas, the mixture typically must be hot and diluted. The cooling process will cause the material to contract and evaporate diluents which leave channels where the acid can still travel and penetrate through to the steel shell. This method will typically provide relief for 1 -2 years.

| Repair Method | Lifetime | Annual Cost |

| EPOXIGARD HC Injection | 10+ years | $60-100k*, One planned downtime |

| Steel Patches | < 1 year | $20k/year, Annual recurring downtime with loss of production of about+ 800 k/day |

| Potassium Silicate Box | < 2 years | $20k/year, Annual downtime with loss of production of about+ 800 k/day |

| Asphaltic Mixture | < 2 years | $15k/year, Annual downtime with loss of production of about+ 800 k/day |

*In addition, the EPOXIGARD will extend the life of the tower buffering structural integrity